Engineering: Design for Manufacturability

State of the Art Engineering Services

The team at Fusion Fabricating and Manufacturing provides industry-leading engineering and manufacturing services for our many clients. Our ISO 9001:2015 certified shop provides the highest quality products and services to meet the most exacting client specifications. Each team member contributes to our commitment to continuous improvement. Our in-house design and engineering department is here to ensure you get the products you need quickly, efficiently, and with the highest quality.

We provide turnkey sheet metal engineering and manufacturing solutions for diverse industries, from aerospace and military to appliance, automotive, medical, and theater/amusement. Our extensive experience across various industries is why customers choose us to help them develop their custom applications, systems, and processes for both new and existing products. No matter your industry or application, our team has the capabilities to design and build your custom manufactured solutions.

Engineering for Manufacturability Process Highlights

Our engineering team excels in taking customer designs and transforming them using our advanced technology and techniques to streamline the manufacturing process, resulting in improved function, quality, and cost savings.

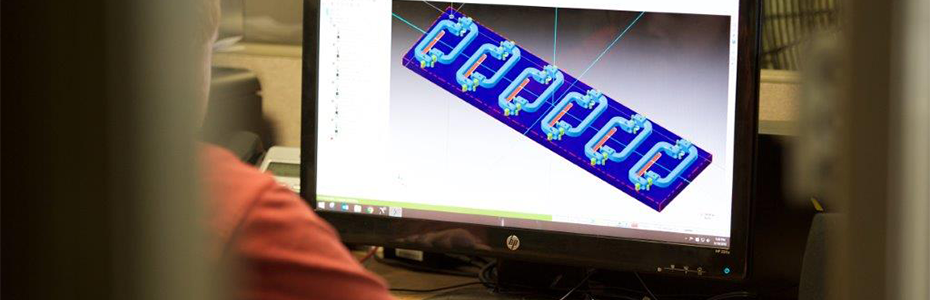

3D Modeling

We use 3D modeling for a variety of functions:

- Document/revision control

- Machine programming

- Project planning

- Redesign for manufacturing with our equipment

- Shop routing

- Quality control

Every project that comes into our facility is 100% 3D modeled. Using this technology, we can eliminate waste, verify the design, optimize for use with our leading-edge equipment, improve quality, and streamline brainstorming and communication.

Continuous Improvement

Our team never follows the status quo. Continuous improvement is built into everything we do. Our engineers are not just sitting in offices. They are on the shop floor, observing machines, techniques, and processes. This is how they’ve achieved breakthroughs in design, increasing the efficiency, functionality, and most importantly for our customers, the cost-effectiveness of the process and the product.

Smart Design

We are committed to finding ways to error-proof our processes. One of the ways we do this is through smart design. By making the initial investment of time in thoughtful and carefully considered design decisions, we can significantly improve both quality and productivity. It allows our team to meet the most stringent and precise design tolerances.

Software and Equipment

We consistently evaluate our software and equipment to ensure that it meets our extremely high standards and provides the services and results our customers require.

Mastercam

This software is actually a suite of CAD/CAM products. It is the #1 solution for manufacturing companies. It streamlines software testing, component manufacturing, tech support, training, and many other processes.

AutoCAD

AutoCAD ensures our designs are accurate. It is invaluable to our engineers for analyzing and solving design challenges for mechanical parts. A vast improvement over manual drawings, AutoCad allows for very quick adjustments. It can allow us to quickly create 3D models from a basic drawing for accurate prototyping and makes exporting, editing, or printing digital designs easy.

Tebis

This CAD/CAM software is a CNC simulator that allows us to plan, program and verify our NC machining operations with all components. We use it to manufacture individual parts or models, molds, and dies. It saves a tremendous amount of time, effort, and money by simulating complex operations on the digital simulation of the actual equipment.

CNC Cutting Equipment

Computer numerical control cutting machines enables our team to scale production when large quantities of products are needed. It ensures even complex cuts are executed accurately and consistently by executing multiple instructions from a computer program. CNC operations replace engineer-operated equipment with automation that delivers highly precise results. Our CNC cutting equipment is accurate to within 0.005″.